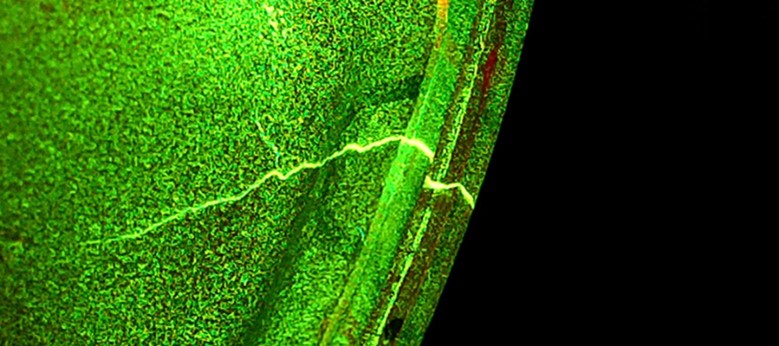

Magnetic particle inspection (MT) is used for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt and some of their alloys. MT is performed by inducing a magnetic field in a ferromagnetic material and then dusting the surface with iron particles. If there’s is a surface-breaking flaw, the magnetic field is distorted, causing local magnetic flux leakage around the flaw. This leakage flux is displayed by covering the surface with very fie iron particles applied either dry or suspended in a liquid. The particles accumulate at the regions of flux leakage, producing a build-up which can be seen visually even when the crack is very narrow.

MT is highly portable, generally inexpensive, and does not need a stringent pre-cleaning operation. It is also one of the best options for detecting fine, shallow surface cracks. MT is fast, easy, and will work through thin coatings.

Magnetic particle testing (MT) is very sensitive test method. It can detect tight in-service fatigue cracks in rotating parts or creep cracks on steam piping.

Magnetic Particle Inspection (MT) cannot be used for non-ferrous materials and non-magnetic ferrous materials such as austenitic stainless steels.