Pulsed eddy current is an advanced electromagnetic inspection technology used in detecting flaws, measuring the thickness of steels and detecting corrosion in ferrous materials typically hidden under layers of coating, fireproofing or insulation.

A magnetic field is created by an electrical current in the coil of a probe. When the probe is placed on the insulation, fireproofing, or coating, the field penetrates through all the layers and stabilizes in the component thickness, and then the electrical current in the transmission coil is turned off, causing a sudden drop in the magnetic field. As a result of electromagnetic induction, eddy currents appear in the component wall. The eddy currents diffuse inward and decrease in strength. The decrease in eddy currents is monitored by the PEC probe and used to determine the wall thickness. The thicker the wall, the longer it takes for the eddy currents to decay to zero.

PEC is therefore the analysis of transient eddy currents in a conductive component following a sharp electromagnetic transition.

Pulsed eddy current can be used:

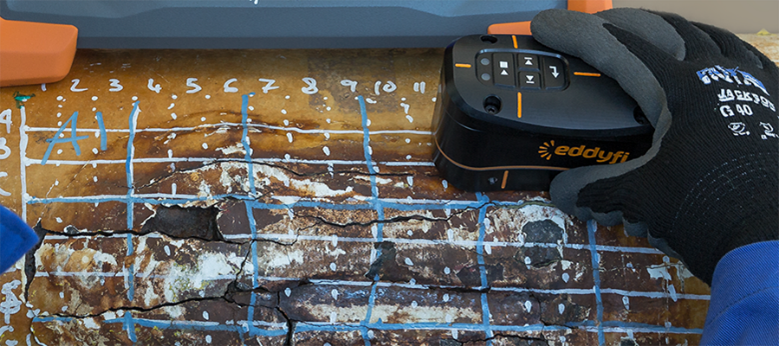

- On outer surfaces with or without insulation or aluminium, stainless and galvanized steel weather jacket, blistering scabs, or fireproofing

- Near pipe elbows, supports, valves, and other metallic structures such as nozzles, and flanges

- Through concrete, polymer coatings, metallic mesh, and rebars.